Demand Control Ventilation

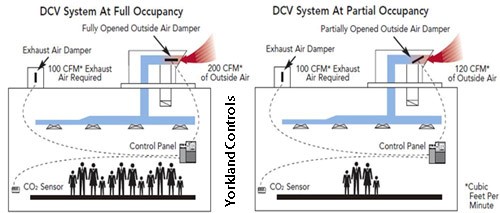

Ventilation can be reduced during the many hours of operation when spaces are vacant or at lower than peak occupancy. When ventilation is reduced, building owners or operators save energy because it is not necessary to heat or cool as much outside air. In colder climates, heating for ventilation air is greater and DCV saves the most energy

Demand Control Ventilation Systems Components that control outside air are already required in most systems. These components could include an economizer or air makeup unit with modulating dampers. Other components needed for DCV are control sensors to measure occupancy, and a controller or DDC programming to communicate either directly with the economizer controller or with a central control system. Occupancy can be measured in one of several ways:

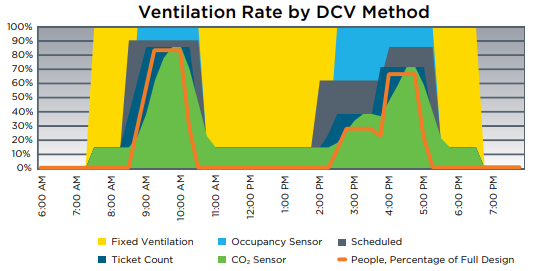

• Space Carbon Dioxide (CO2) Sensing is the most common method. These systems have a CO2 sensor in each space or in the return air and adjust the ventilation based on CO2 concentration. Because people breathe out CO2, the higher the level, the more people are in the space relative to the ventilation rate. With a CO2 sensor DCV system, the ventilation rate varies based on the number of people in the space.

• Occupant Counting uses turnstiles, ticket sales, video recognition, security swipes, or other methods to obtain an actual or estimated count of occupants in the space. Like systems with CO2 sensors, the ventilation rate varies based on the number of people in the space.

• Occupancy Sensing uses lighting or dedicated occupancy sensors to detect if anyone is in the space or if the space is vacant. For occupancy sensing, either full ventilation or area ventilation is provided, so full ventilation will be provided whether there is one person in the space or the space is fully occupied.

• Scheduled Ventilation can work effectively with classrooms or scheduled meeting rooms. In this system, the occupancy is estimated based on a class or rental schedule and this information is input into the control system. To be effective, the system requires ongoing entry of schedule information or integration with a scheduling calendar system.

• Supply Air CO2 Concentration Maintenance can be applied to a large multi-zone variable air volume system. In this approach, the required ventilation rates are calculated for design conditions in each zone and the CO2 concentration in the supply air needed to meet that design ventilation rate is determined. Then the outside air rate is adjusted based on a supply air CO2 sensor to meet the predetermined rate. Any of these methods will meet the requirement for DCV. For a base-case ventilation system without DCV, the design ventilation required when the space is full would be determined, including both the area and people ventilation rates. We will refer to that as the full ventilation rate. (Some designers may use the term minimum ventilation for area ventilation and maximum ventilation for full ventilation.) Without DCV, that full ventilation rate is provided whenever the space is expected to be occupied. With DCV, the area ventilation rate is provided whenever the space is expected to be occupied. When occupancy is detected or scheduled with one of the methods described, the ventilation is increased from the area rate to either the full rate or somewhere between the area and full rate.